Organica Wastewater

Is it a wastewater treatment plant or a garden?

This picture is inside an Organica wastewater treatment plant in France and it treats 3.5 MLD of wastewater. Its one of many new Organica systems being used around the world.

Organica is a natural treatment system combining conventional wastewater treatment technology with a botanic ecosystem. Organica uses plant roots that grow into the effluent encouraging bacteria and living organisms to develop.

This creates a completely natural form of treatment providing significant reductions in space, energy use and operating costs.

An Organica plant is designed to look like a greenhouse or garden and is now available in the Australian market, but only from Hydroflux®.

Find out more

Fixed-Bed Biofilm Activated Sludge (FBAS)

Fixed-Bed Biofilm Activated Sludge (FBAS)

Fixed-Bed Biofilm Activated Sludge (FBAS) is a type of Integrated Fixed Film Activated Sludge (IFAS) system that leverages the use of various natural AND engineered media to provide a habitat for a diverse fixed-film bacterial culture which metabolizes the contaminants in wastewater.

These populations of organisms live in an attached form on fixed bed media inside the reactors, as opposed to being in constant motion as is the case with conventional solutions such as Activated Sludge or MBBR.

Natural Media

Natural Media

Providing a stationary habitat allows an incredibly diverse and robust biofilm to grow and thrive inside the reactors, ultimately offering significantly improved nutrient removal, energy efficiency, and resiliency, all in much less space than conventional approaches.

With nearly two-decades of experience in the development and design of fixed-film wastewater treatment solutions, Organica’s FCR (Food-Chain Reactor) represents the best-of-breed in FBAS wastewater treatment plants (WWTPs).

Organica Food Chain Reactor (FCR)

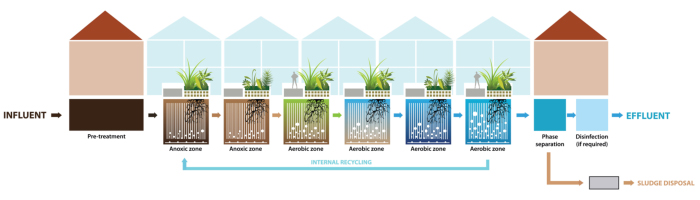

The Organica FCR is a complete wastewater treatment solution including solids removal, biological treatment/nutrient removal, phase separation, and final treatment for reuse quality (if required), all incorporated into a compact, single structure.

The biological treatment step is accomplished via a series of reactors, whose number and size depends on a variety of factors including influent wastewater characteristics, effluent requirements, temperature, and the capacity of the wastewater treatment plant (WWTP).

The biological stage is preceded with a standard pretreatment step and followed by phase separation and final polishing to meet the client’s specific effluent requirements.

The biological reactors in an Organica FCR are arranged in a cascade configuration, each with specially designed Biomodules, in order to optimize the development of distinct ecosystems in each step of the treatment process.

Following primary treatment the influent travels through the biological cascade, and in doing so the nutrient content is consumed by biofilm cultures that live on both the engineered (Organica’s proprietary biofiber media) and natural (plant roots) media in each reactor.

As a result of the cascade design the composition of the ecosystem fixed in the biofilm changes from reactor to reactor, adapting itself to the decreasing nutrient concentrations, thus maximizing the decomposition of contaminants and enabling Organica FCR WWTPs to treat wastewater in the least amount of space, using as little energy as possible.

While Organica and Hydroflux Epco provide the key enabling products and services for the design, construction, and operation of an Organica FCR WWTP, the majority of other components in an Organica FCR WWTP are commercially available “off-the-shelf” and can be provided by any EPC of General Contractor.

For further information please call Hydroflux Epco on 1300 417 697 or email [email protected]

The Organica Food Chain Reactor (FCR) is a complete wastewater treatment solution including solids removal, biological treatment/nutrient removal, phase separation, and final treatment for reuse quality (if required), all incorporated into a compact, single structure and offers numerous advantages compared to conventional approaches.

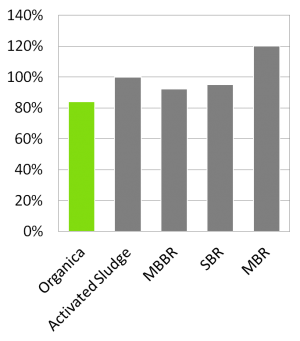

Significant footprint reduction drives CAPEX savings.

How does Organica reduce the physical footprint of a WWTP?

As a result of the use of both plant roots and Organica’s proprietary bio-fiber media as fixed film carriers, Organica FCR WWTPs typically hold about 12-18 kg of biomass per cubic meter of reactor space.

This concentration of biomass is 3 to 4 times more than conventional solutions such as Activated Sludge.

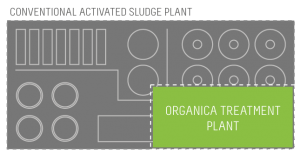

With 3-4 times as many “hungry mouths” consuming the nutrient and contaminant content in the wastewater in same amount of space, Organica FCR WWTPs are typically 50-75% smaller than an Activated Sludge WWTP would be for the same quantity and quality influent.

Construction costs less, even without considering land value.

How much does it cost?

Smaller footprint means land cost savings, but it also means less concrete, less steel, and less general equipment.

As a result, even without including land costs, for same quality and quantity of influent Organica FCR WWTPs have a lower capital cost than conventional solutions.

Ask for a quotation today and compare the competitiveness of Organica FCR for your project!

For further information please call Hydroflux Epco on 1300 417 697 or email [email protected]

As populations continue to grow, cities – especially in the developing world

– are becoming more and more crowded, while in other parts of the world “urban sprawl” is graying the lines between what is “urban” and “suburban.”

As a result, land is becoming scarcer and land values near population centers continue to rise. Governments can no longer afford to waste valuable space on WWTPs and the odor and unattractive aesthetics that causes people to live far away from them, not to mention the high cost of building and operating the infrastructure to take the wastewater and effluent to and from the remote WWTP location.

With an attractive greenhouse design and none of the typical wastewater treatment plant odors, the garden like appearance of an Organica FCR offers a significantly reduced geographic and “psychological” footprint, dramatically reducing infrastructure costs by allowing wastewater to be treated close to the source.

For further information please call Hydroflux Epco on 1300 417 697 or email [email protected]

The ideal solution for today’s ever-changing world.

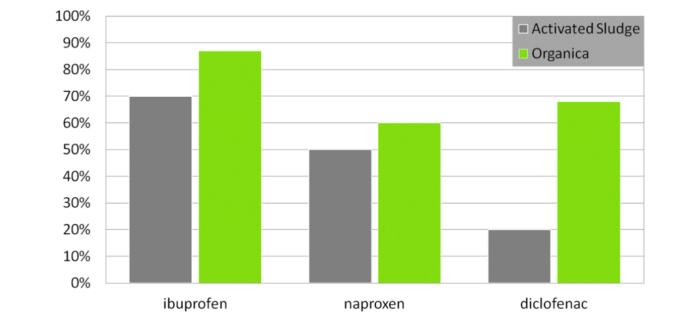

Due to the higher quantity and diversity of biomass that lives on the natural and artificial media in an Organica FCR, a wider spectrum of organics is broken down.

The result is that for the same quantity and quality of wastewater an Organica FCR will produce lower Chemical Oxygen Demand (COD) and Total Nitrogen (TN) when compared to conventional approaches, while we also see enhanced removal of other “hot topic” contaminants such as xenobiotics found in common in painkillers.

As a result of the unique ecological diversity enabled by our FBAS solution, Organica FCR WWTPs are highly resilient to changes in influent. We have found this is especially relevant in emerging markets, where at times industrial flows can unpredictably mix with municipal flows and threaten entire biological WWTPs. While killing any ecosystem is only a matter of resolve, the additional diversity in an Organica FCR means the system can adapt to rapid spikes in influent much more effectively than other approaches, making an ideal solution for today’s unpredictable world.

For further information please call Hydroflux Epco on 1300 417 697 or email [email protected]

From companies to municipalities, Organica provides water solutions for each individual situation.

With over 50 operating references in Europe, China and Nth America, the Organica FCR process has been well established with advanced modelling tools for process and engineering design.

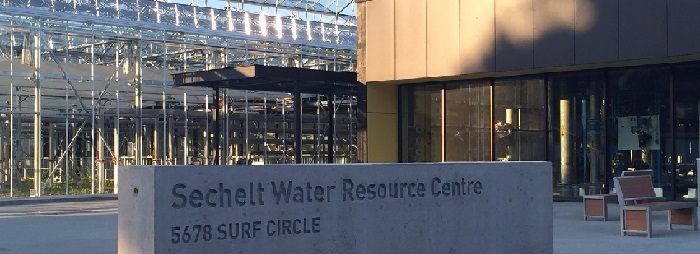

Sechelt, Canada

Located on the pristine lower “Sunshine Coast” of British Columba, north of Vancouver, the town of Sechelt selected an Organica powered wastewater treatment facility due to its garden like appearance, odourless operation, small footprint and energy efficiency. The Organica solution allowed the treatment plant to be constructed in the middle of town, further reducing pumping and collection costs. Two existing treatment facilities were made redundant, with all flows being treated in the new 2.2 MLD facility.

<View the Sechelt, Canada Case Study

Budapest, Hungary

An 80 MLD wastewater treatment facility in the Hungarian capital of Budapest has been completely enveloped by the growth of the city, creating capacity, operational and odour challenges. To upgrade the facility and address these issues at the aging treatment facility, Organica FCR was chosen as the most economical solution.

<View the Budapest, Hungary Case Study

Shenzhen, China

On the Chinese mainland across from Hong Kong, Shenzhen is a city booming with industrial expansion. One of the area’s operations is Foxconn Technology Group’s largest manufacturing plant, located in the middle of the city, where several hundred thousand people live and work. In accordance with new national regulations, the site is required to provide wastewater treatment to meet the business park’s needs, and produce clean, reusable water. To meet those needs, an Organica solution was squeezed into the bustling area and provided a valuable green space for residents.

<View the Shenzen, China Case Study

Etyek, Hungary

When a group of Hollywood producers presented the idea of building a world class film studio in Etyek, Hungary (just outside of Budapest), the proposal was limited by the community’s ability to handle the increased wastewater production. To facilitate the studio construction and bring valuable jobs and tourism to the small community, Etyek’s wastewater system was expanded to meet the increased demand with an Organica solution, all with a design blending into the surrounding wine country hillside.

<View the Etyek, Hungary Case Study

Gençay, France

Located in Western France, Gencay is a small community recognized as a medieval heritage site complete with a 13th-century fortress located in the city center. When facing new water quality standards, Gençay worked together with the neighboring town of Saint-Maurice-La-Clouere to find a wastewater solution that fits into the local setting, only Organica could provide an aesthetically-pleasing solution to enhance the local surroundings.

<View the Gençay, France Case Study

Telki, Hungary

Telki is a charming and rapidly growing community in the the countryside outside of Budapest (Hungary). As the residential community grew, it needed a wastewater solution that upheld the high local standards while not disturbing or lowering the existing community’s land and real estate value. Organica’s odorless and compact design fit into the limited available space, all while upholding the community’s high expectations and using less energy than conventional approaches.

<View the Telki, Hungary Case Study

Gallicoop, Hungary

Gallicoop Corp. is one of the largest food processing operations in Eastern Europe. As the local public utilities imposed higher fees for treating the wastewater produced at the facility, Gallicoop needed a business-friendly solution for onsite processing of their wastewater. To solve the challenge, Organica delivered both a business-friendly solution, but an environmentally-friendly one as well.

<View the Gallicoop, Hungary Case Study

For further information please call Hydroflux Epco on 1300 417 697 or email [email protected]

Fitting into population centers.

The Organica FCR is the perfect solution for the unique wastewater treatment challenges facing today’s municipalities.

The combination of a small geographic footprint, lower energy consumption, and enhanced treatment characteristics offers a compelling value given the financial difficulties faced by so many cities and towns across the world.

And with an attractive greenhouse design and none of the typical wastewater treatment plant odor an Organica FCR can be located virtually anywhere, reducing infrastructure costs and offering the potential to become a new kind community building, a place for environmental education, recreation, and quiet enjoyment.

Organica solutions provide:

- 50%-75% Smaller footprint

- More than 30% lower energy consumption

- Odor-free and attractive aesthetics

- More resiliency to changes in influent

This is why over 25 municipal customers currently have Organica-powered WWTPs operating in their cities and towns, with dozens currently under construction. Organica can design FCR WWTPs in sizes ranging from 1,000 m3/d to 200,000 m3/d and more.

For further information please call Hydroflux Epco on 1300 417 697 or email [email protected]

The Organica FCR can Upgrade and Improve Existing WWTPs.

In developed economies, much of the wastewater infrastructure is aging well beyond its original life or operating in excess of its rated capacity.

In addition, many WWTPs are failing to meet increasingly strict effluent requirements, resulting from authorities’ efforts to ensure no hazardous contaminants are discharged into the rivers, lakes, and oceans. Organica transforms these unattractive, foul-smelling, deteriorating, obsolete WWTPs into odour-free botanical gardens that:

- Can accommodate 2-3 times their original capacity in the same space

- Can treat the same influent in 50-75% less space, freeing up valuable land for other purposes

- Improve BOD and nutrient removal> to meet more stringent effluent limits

- Are more resilient to fluctuations in influent

Hydroflux Epco and Organica can upgrade WWTPs of almost any size with the Organica FCR solution.

For further information please call Hydroflux Epco on 1300 417 697 or email [email protected]

Biological Treatment for Industrial Wastewater.

Organica FCR works well with many forms of industrial wastewater including.

- milk

- cheese

- meat processing

- pulp and paper

- breweries

- slaughterhouses

- biogas

While an Organica FCR solution can be applied for the biological treatment step in any industrial application, the economic benefits are most prevalent in industries where the contaminants are of organic origin.

Organica FCR provides a unique value proposition, offering substantial savings on both capital and operating costs. In addition, the attractive “look and feel” and small footprint allows the WWTP to be located close to the manufacturing plant, providing access to treated water that can be reused during the fabrication process, translating into important savings on your water bill.

For further information please call Hydroflux Epco on 1300 417 697 or email [email protected]

Conserves valuable land with a small footprint and unmatched aesthetics.

In today’s environmentally conscious world real estate developers are increasingly required to account for how wastewater will be treated before selling any land.

rganica FCR provides the ideal solution to meet this challenge, offering a small geographic footprint and attractive aesthetics which mitigates any negative impact on land value and ultimately offer the developer more land to sell.

In addition, if water scarcity is a bottleneck for the development, Organica FCR limits infrastructure costs and thus enables cost-efficient wastewater recycling. In fact, Organica was recently chosen by Marubeni – one the largest real estate developers in Southeast Asia – to provide a wastewater treatment for one of its business parks in Indonesia.

Click here to learn more about how Organica works with developers Download Working With Developers PDF

For further information please call Hydroflux Epco on 1300 417 697 or email [email protected]

Water scarcity is one of the biggest challenges humanity is facing.

Approximately 2.5 billion people –1/3 of the world’s population – live in areas that the World Bank characterises as “water stressed.” In 15 years, this will be 2/3 of the world’s population.

As the world looks to address this incredible challenge, undoubtedly recycling of wastewater will be a key part of the solution.

With its small geographic and “psychological” footprint and high quality effluent, the Organica FCR solution is ideally designed to meet this need. The odorless, garden-like appearance of an Organica FCR allows near unlimited flexibility in WWTP location, ultimately reducing infrastructure requirements by allowing the WWTP to be located close to the “point of use.”

The result is a highly economic solution to global water scarcity challenges, which can be applied at WWTPs of any size in virtually any geographic location.

For further information please call Hydroflux Epco on 1300 417 697 or email [email protected]

Commercial establishments such as office parks, airports, hotels and resorts are increasingly looking to their own wastewater treatment and recycling solutions.

These businesses waste thousands of liters of drinking water every day on sprinkler systems, cooling towers, toilet flushing and other non-potable needs. With the space and cost-efficient Organica FCR solution these businesses can place a WWTP directly on site, replacing the need to pump wastewater to a far-off utility company and using recycled effluent in place of drinking water. This drives significant cost savings and also serves as a valuable marketing tool to an increasingly environmentally conscious consumer base.

For further information please call Hydroflux Epco on 1300 417 697 or email [email protected]

The essential components to realise an Organica FCR WWTP.

While the majority of components in an Organica FCR WWTP are commercially available “off-the-shelf” and can be provided by any EPC or General Contractor, Organica & Hydroflux Epco provide the key enabling products and services that power the Organica FCR solution.

Organica products & services include: – links in orange

A fully standardised and packaged basic WWTP Design that can be used by any GC/EPC contractor to construct an Organica-powered WWTP

Organica Bluehouse, a containerised Organica facility

Organica Biomodule

Organica Scallop Discfilter units for phase separation

Process Control Software

Operational Supervision, support and operator training

Operation and Maintenance manuals for equipment and systems designed/supplied by Organica

Hydroflux Epco products & services include: – links in orange

Complete Inlet Works from HUBER Technology

Sludge Dewatering Equipment from HUBER Technology

AEROSTRIP Fine Bubble Aeration Systems from AquaConsult

WWTP Operation by Hydroflux Utilities

Hydroflux Epco & Organica can also provide additional products and services including, detailed design, project management, plant maintenance, operation and commodity supply and other specially requested products and services.

For further information please call Hydroflux Epco on 1300 417 697 or email [email protected]

A complete Organica FCR solution, pre-designed and assembled for installation.

A complete Organica FCR solution, pre-designed and assembled for installation.

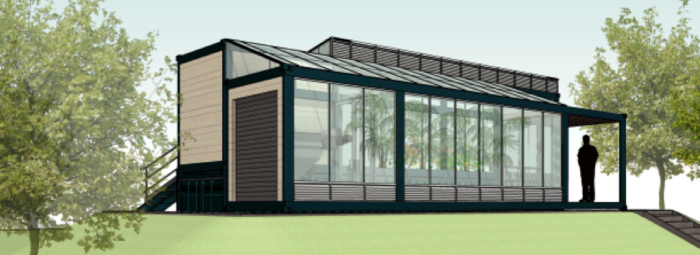

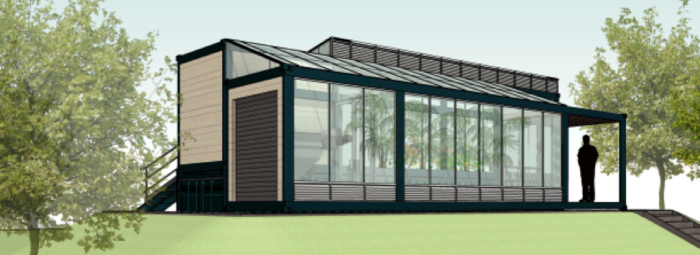

Organica Bluehouse is a complete Organica FCR-powered wastewater treatment and reuse solution, pre-assembled and containerised. Like all Organica facilities, Bluehouse offers compact, odourless and energy efficient treatment, all while providing a unique, botanical garden-like look and feel. As a result, Organica’s Bluehouse is an ideal choice for sustainable wastewater treatment and reclamation in lower flow applications.

Applications and advantages

Organica Bluehouse is a perfect solution for smaller-size applications, including small communities, real estate development projects, hotels or resorts.

True Organica solution: odourless operation and attractive appearance with compact physical footprint

Pre-designed to allow rapid manufacturing and delivery

Factory-assembled for easy installation with minimal site work

Reliable and simple to operate with low staffing needs

Reuse quality effluent, which may be used for irrigation, cooling towers, and for other non-potable purposes

Onsite treatment eliminates need for sewage network connection

Preserves land value by reducing “psychological” footprint

For further information please call Hydroflux Epco on 1300 417 697 or email [email protected]

Standard Organica FCR Designs For Decentralised Applications

Organica Villa is a complete Organica FCR-powered wastewater treatment and reuse solution that has been pre-designed in four sizes from 0.2 to 2MLD. The standardisation reduces upfront design time associated with detailed engineering. Like all Organica facilities, the Villa concept offers compact, odourless and energy efficient treatment, all while providing a unique, botanical garden-like look and feel. As a result, Organica’s Villa is an ideal choice for sustainable wastewater treatment and reclamation in lower flow applications.

Applications and advantages

Organica Villa is a perfect solution for smaller-size applications, including small communities, real estate development projects, hotels or resorts.

True Organica solution: odourless operation and attractive appearance with compact physical footprint

Standard designs to allow rapid manufacturing and delivery

Reliable and simple to operate with low staffing needs

Reuse quality effluent, which may be used for irrigation, cooling towers, and for other non-potable purposes. Class A+ systems can be added as tertiary treatment

Onsite treatment eliminates need for sewage network connection

Preserves land value by reducing “psychological” footprint

For further information please call Hydroflux Epco on 1300 417 697 or email [email protected]

At the heart of the Organica Food Chain Reactor (FCR) solution is the Organica Biomodule. Designed to fit securely into the biological reactors, each Biomodule acts as the support structure for both the plants whose roots make up the primary biofilm carrier, and Organica’s specially developed proprietary biofiber media designed to mimic the structure and function of the plant roots.

The root structures in turn provide an ideal habitat for a thriving ecosystem – both larger (3-4x greater active biomass per cubic meter of reactor volume) and more diverse (4x greater species diversity) than the biology found in typical conventional activated sludge based systems.

This results in the development of a distinctive self-regulating ecosystem with operational flexibility and high resilience to unexpected influent fluctuations and shock-loading. In addition, because the Biomodules support this unique biofilm fixed on the root structures, the process utilizes much lower suspended solids content in the water (typically 90% less than conventional suspended growth systems). This lower suspended solids content improves oxygen transfer efficiency and results in 30% or greater energy savings.

The Biomodule is the key component of an Organica FCR WWTP, enabling the same level of contaminant/nutrient removal in half (or less) reactor volume when compared to other activated sludge-based solutions. This volume reduction results in land, construction, and equipment cost savings.

For further information please call Hydroflux Epco on 1300 417 697 or email [email protected]

Because the biomass in an Organica Food Chain Reactor (FCR) is primarily fixed on the root structures, suspended solids (TSS) content of the water at the end of biological treatment is significantly (commonly 90%) lower than conventional suspended growth systems (100-300 mg/l). As a result, an Organica FCR WWTP can perform phase separation via discfilter units instead of space-consuming sedimentation tanks (secondary clarifiers). Each Scallop discfilter incorporates a simple, yet sophisticated, design that ensures continuous and low-maintenance operation.

Organica’s Scallop discfilter is a mechanical cloth filtration device specially designed to remove suspended solids.

Designed as an “inside-out” system, water flows into the Scallop discfilter feed pipe and through openings into the discs mounted on the feed pipe. As the influent flows through the filter panels, suspended solids collect on the filtration media surface. The solids accumulate and generate headloss, which causes the feed pipe water level to rise until hitting a set point, triggering the automated backwash cycle. During backwash, the accumulated solids are washed from the rotating discs into the sludge trough by a small portion of the filtered water under pressure. Filtration is continuous even during backwash, and the design of the discfilter enables water to gravity flow through the whole system, minimizing pumping energy.

The design also allows for simple and easy access to individual filter panels for easy maintenance or replacement.

For further information please call Hydroflux Epco on 1300 417 697 or email [email protected]

Highly automated system allows seamless operation.

As part of each Organica FCR WWTP, Organica supplies and installs its process control software, custom programmed to operate the WWTP efficiently and in an automated way. Organica utilises a PC-PLC based process control system, integrating the acquisition, display, and storage of operational data, as well as the input and application of operational variables.

The control and management of the WWTP relies on the data gathered from the sensors and probes installed in the WWTP, provided by either Organica, Hydroflux Epco or a 3rd party. The flow of wastewater is measured by electromagnetic meters and level indicators, while the optimization of energy consumption requires data from dissolved oxygen probes linked to variable speed drives controlling the blowers. Pump capacity is regulated via variable speed drives and electromagnetic or pneumatic controllers which regulate valves. All equipment is controlled by a PLC, which monitors their status through feedback channels and displays it on the application program.

The process control software provides an easy-to-use graphical interface for operator interaction and ensures secure operation of the whole treatment plant. The operational savings from this high level of automation are significant as with this level of sophistication Organica facilities require very few personnel for safe operation. In addition, the ability to establish secure online connections enables Organica engineers to provide clients with an Operational Supervision service. Using the online interface, engineers can remotely view, evaluate, and provide input to optimise WWTP operation.

For further information please call Hydroflux Epco on 1300 417 697 or email [email protected]

Everything needed to construct an Organica FCR WWTP.

Every Organica FCR begins with process design. This is Organica’s core expertise; we design a wastewater treatment process which produces clean effluent in very little space, with minimal energy consumption.

Each process design starts with basic parameters from the client including the influent water characteristics, effluent discharge limits, temperature, available space, and required treatment capacity.

Organica then carries out careful calculations and creates a process flow diagram and a set of parameters which govern the operation of that particular Organica FCR solution. This data is then supplemented with additional detail from our engineering team to produce a full WWTP design package, including basic architectural drawings and a complete equipment list. The result is a complete toolset which can be used by any EPC or General contractor to build that specific Organica FCR WWTP.

Organica has developed a first-of-its-kind design tool that will launch in late summer 2014. The tool allows us to input all the specific details of a project, including commercial preferences, influent, effluent, flows, temperatures, and client preferences. We then validate that data based on our extensive regional databases and process validation algorithms. Once the data passes these checks it is used for simulation, sizing, and rendering to create a COMPLETE basic engineering design package for a beautiful, space and energy-efficient Organica-powered wastewater treatment facility. The tool will help us in facilitating the value-creating change that Organica-powered facilities offer to cities and towns all over the world.

We can build or upgrade WWTPs of almost any size with the Organica FCR solution.

For further information please call Hydroflux Epco on 1300 417 697 or email [email protected]

Supervision and Optimisation.

Once a plant is commissioned, Organica offers WWTP plant operators three different Operational Supervision Service packages designed to optimise performance, and ensure the operator receives the appropriate level of technology support through the entire life of the WWTP. These packages are designed to facilitate anything from easy operation of the WWTP to data analysis to energy minimization suggestions, depending on the needs of the client. Note that these services do not contain routine local assistance from the Organica crew; such options are subject of separate agreements.

In all packages, using the built-in protocols of the process control software, the respective WWTP is connected to Organica’s central server. All operational data is fed into sophisticated mathematical models driven by artificial intelligence systems. These systems allow Organica to conduct special pattern matching and recognition protocols, helping extend the capabilities of the local process control software and fine tuning the parameters of the local system (if necessary) to optimize performance.

The service can also contain periodic reviews from Organica’s process experts who, based on the data and evaluation, compile a monthly report focusing on strong and weak points of the operation, along with suggestions for improvements in terms of both water quality and economic improvements (e.g. energy consumption).

For further information please call Hydroflux Epco on 1300 417 697 or email [email protected]