Sludge Thickening

There are over 1000 HUBER thickeners installed worldwide including many in Australia. The rotary screw thickener is designed for thickening of waste activated sludge prior to dewatering or stabilisation at larger STP’s.

Good sludge thickening is required as a prerequisite for the efficient further treatment or dewatering of sewage sludge.

The HUBER ROTAMAT® Screw Thickener RoS 2 is a very high performance efficient system for thickening waste activated sludge.

It is a compact and fully enclosed system with very low operational costs, reliable and requires minimal operator attention.

The HUBER ROTAMAT® Screw Thickener RoS 2 is designed to handle sludge flows up to 80m3 per hour.

Find out more

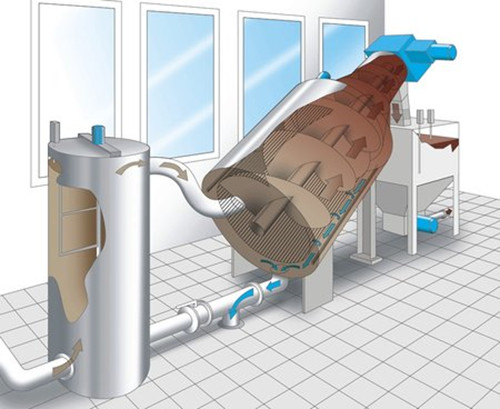

The screw thickener consists of a cylindrical wedge section basket which retains the solids contained within the fed sludge.

A screw, slowly rotating with variable speed conveys the solids gently upward through the inclined basket. Water drains through the basket.

The degree of thickening is adjustable by means of a height adjustable weir plate in the sludge discharge and the variable screw speed.

A rotating spray bar cleans the wedge wire periodically from the outside during screw operation

- highest sludge thickening performance

- sludge volume reduction by up to 80 %

- sturdy design for high solids loads and coarse material containing sludge

- maximum system availability due to the virtually wear-resistant and clog-free stainless steel wedge

- wire basket

- high operational reliability due to the slow screw speed

- low power and spray water consumption

- no need for lubrication

- completely enclosed

- no vibration

- low noise < 68 dB(A)

The STRAINPRESS® can be used in a variety of applications including

- primary sludge

- secondary sludge

- mixed sludge

- septic sludge

- floating sludge

- grease sludge

- digested sludge

- production wastewater and industrial sludges

- circulation and process water