Dissolved Air Flotation

Hydroflux is proud to be Australia’s first water treatment and technology company to achieve Climate Active carbon neutral certification for our entire organization. As part of our climate change mission, we continue to research, develop and invest in sustainable technologies.

Now our journey continues – our main range of water technology and associated chemical products are Climate Active certified as carbon neutral. To read more on our journey, click HERE

The HyDAF Dissolved Air Flotation (DAF) system’s simplicity and exceptional performance in municipal applications are just two of the reasons why the HyDAF is the Dissolved Air Flotation system of choice for Municipal Water Authorities today.

• Australia’s most experienced water and wastewater treatment company

• Dissolved Air Flotation systems to suit Potable Water, WAS and Algae Removal Processes

• Nationwide project delivery capability

For expert advice, please call 1300 417 697

Please click on one of the links below for additional information or the tabs for photos, drawings, case studies and brochures:

Find out more

Key Features of the HyDAF Wastewater Dissolved Air Flotation system

A HyDAF HD Dissolved Air Flotation system comprises the following main components within one packaged plant:

- Hydroflux Hex Inlet Mixer to provide superior inlet flow distribution and flocculent / recycle stream mixing for optimum flotation.

- Integrated Sludge hoppers for easy settled solids removal. Optional integrated bottom screw for WAS applications.

- Dissolved air recycle stream injection into the Hydroflux Hex Inlet Mixer for immediate air contact with flocculent and solids particles.

- Flotation zone (DAF Zone) to provide a quiescent volume for the formation of float.

- Heavy duty, fully guarded, counter-current surface skimmer for the removal of surface float.

- Effluent discharge baffle to enhance the separation of the clarified effluent from the quiescent volume.

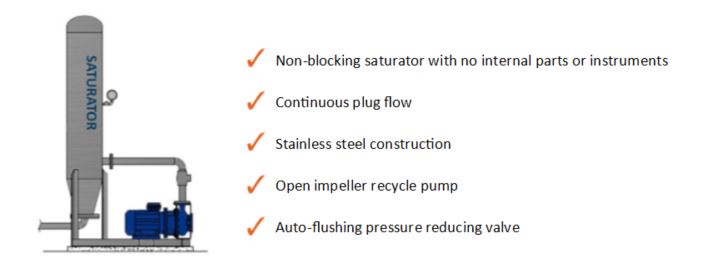

The most simple, effective and reliable dissolved air production system ever!

This micro-bubble precipitation is achieved through the following steps:

- First a recycle stream of treated effluent is taken from the discharge end of the HyDAF and is pressurised to a pressure of 400-600kPa.

- This pressurised flow is injected into specially designed process pipework called a Saturator. Air is added to the Saturator to maintain a “headspace” which acts to provide contact between the air and the treated effluent and it is here that air is dissolved into the recycle stream.

- To precipitate the dissolved air back as micro air bubbles, the pressure is relieved through a Pressure Regulating Valve (PRV). The PRV creates back pressure against the Recycle Pump and establishes the pressure in the system, and in the Saturator. This valve also provides for a high level of shear which aids in the precipitation of the air from the pressurised solution.

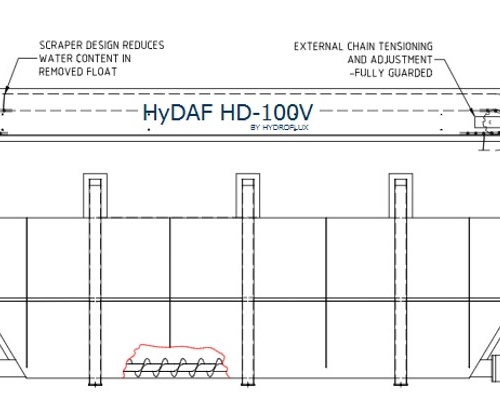

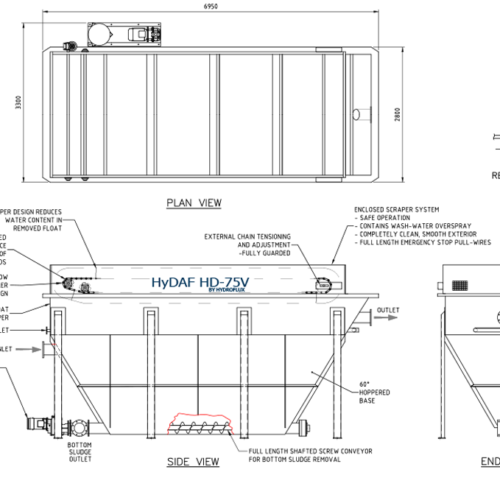

The HD-V series which is designed with a steep hopper base fitted with a screw conveyor. The V series allows removal of settled solids automatically, without the need to drain the DAF. It is ideal in applications where grit or other substances that do not float are abundant in the wastewater.

The HD-V system is designed with the same inlet mixing system as the standard HD series, however, the unit features steep sloping sides and a screw is installed in the base.

The HD-V units utilise the velocity of the dissolved air recycle stream to thoroughly mix the air microbubbles throughout the incoming influent stream. The recycle stream is introduced into the influent stream at a 45° angle, after which the combined stream enters a hexagonal shaped chamber which promotes mixing. This results in an even distribution of dissolved air throughout incoming influent and ensures that the microbubbles have the best chance to contact incoming solids and any fat, oil and grease.

The conveyor screw is designed to remove any settled solids and sludge out of the system. The screw is designed to move the solids towards the drive end of the HyDAF where either an actuated valve or pump can be fitted, depending on the site requirements.

A stuffing box is used to seal the shaft, this technology is commonly used in marine applications to seal propeller shafts on boats. A packing material (braided gland) is wrapped around the shaft and compressed against the end plate by a packing nut, creating a seal.

Hydroflux Epco supply a comprehensive range of HyDAF dissolved air flotation systems to suit virtually every municipal application

| HyDAF HD dissolved air flotation model number | Typical flow range (kL/hr) | Typical WAS Thickening* (kL/hr) |

| HD10 | 5-15 | 2-4 |

| HD20 | 15-25 | 4-8 |

| HD35 | 35-40 | 7-14 |

| HD50 / HD50V | 40-60 | 10-20 |

| HD75 / HD75V | 65-85 | 15-30 |

| HD100 / HD100V | 85-120 | 20-40 |

| HD200 / HD200V | 150-225 | 30-60 |

| HD300 | 250-350 | 45-95 |

| HD500 | 400-600 | 80-150 |

| FlooDAF dissolved air flotation model number | Typical flow range (kL/hr) | |

| FlooDAF49 | 365-425 | |

| FlooDAF65 | 500-625 | |

| FlooDAF115 | 650-750 | |

| FlooDAF149 | 800-990 |

*typical capacities for potable water and algae removal. For WAS thickening, consult Hydroflux Epco for detailed sizing information

FlooDAF® Microflotation is a highly efficient dispersion water system suitable for various water or effluent clarification applications. The FlooDAF compliments the HD DAF systems with designs for very large flow rates up to 1000 m3/hr in a single unit.

With more than 500 installations worldwide, this reliable and proven technology has a small footprint and high separation efficiency. It offers excellent performance with low maintenance requirements.

- Automatic sludge and water-level control

- Good tolerance for hydraulic and solid variations

- Low overall capital expenditure and operating costs

- Low maintenance requirements

The Hydroflux Hy-DAF range of Dissolved Air Flotation systems have been applied to a wide range of municipal applications. Listed below are some of the more common ones.

Applications for the HyDAF dissolved air flotation system in Municipal Sewage and Drinking Water Plants include:

- Waste Activated Sludge (WAS) Thickening – with and without polymer dosing

- Potable Water Treatment – raw water clarification from dams, rivers and ponds

- Algae Removal from treatment ponds and lagoons

- Phosphorous Removal from secondary treatment applications

- Pre-Treatment to Advanced Membrane Filtration (MF and UF)

- Seawater Clarification

Frequently Asked Questions – Hydroflux HD-DAF – Dissolved Air Flotation System

“What is the capacity of the range of HyDAF dissolved air flotation systems?”

The HD range of HyDAF dissolved air flotation systems are designed for applications where high solids loads are usually experienced. We have standard sizes that we manufacture but in each case we determine the most suitable model and dissolved air recycle system to suit the specific wastewater characteristics.

“What is the HyDAF HD-V range?”

This is a HyDAF system designed with steep sloping sides and an auger in the base. It is specifically used when the wastewater in question contains a reasonable proportion of settleable solids such as grit from a meat processing plant for example.

“What is the FlooDAF range?”

FlooDAF is designed by Flootech which is one of Hydroflux’s many international exclusive partners. The FlooDAF is an economical range of DAF systems for large flows up to 1000m3/hr.

“Can the HyDAF dissolved air flotation system handle variable load and flows?”

This depends. In applications where chemicals are not being used, the HyDAF dissolved air flotation system can operate and effectively treat wastewater at any flow and solids load up to its design capacity. If chemicals are being dosed, then variations in flow and solids load will adversely effect the chemical process. In these cases, the installation of a balance tank upstream of the HyDAF dissolved air flotation and a constant feed rate is recommended.

“Do I need to dose chemicals into the wastewater?”

Dosing of chemicals into the wastewater upstream of the HyDAF dissolved air flotation system will improve the performance of the system. Whether it is necessary to dose chemicals depends on the water quality that is required. Hydroflux can tailor specific chemical programs to ensure performance requirements are met economically whilst minimising the amount of sludge that will be generated. For more information on our chemical division, please click here to visit the Hydroflux Utilities web site

“How much sludge will the HyDAF dissolved air flotation system generate?”

The amount of sludge generated depends on the amount of solids being removed and also whether chemicals are being dosed to enhance the performance of the HyDAF dissolved air flotation system. The dry solids concentration in the dissolved air flotation system sludge can be up to 10%. You can estimate the amount of sludge that will be generated by multiplying the solids load by the daily flow or alternatively give us a call and we will be able to assist. In larger applications the installation of a sludge dewatering plant will be highly economical. Please click here for information on our range of dewatering systems.

“What is the performance of the HyDAF dissolved air flotation system in terms of pollutant removal?”

The treated water quality depends on the nature of the raw wastewater and the chemical process that is applied. In many municipal applications, the HyDAF dissolved air flotation system can remove over 99% of solids and grease which will result in quite significant reductions in BOD and COD. Nutrients and metals can also be removed using the HyDAF dissolved air flotation process. .

“Does the HyDAF dissolved air flotation system require much power?”

Compared to the overall power requirements of a compelte wastewater treatment plant, the power demand for the actual HyDAF dissolved air flotation system is minimal. The dissolved air recycle pump draws the most power and is fitted with a motor ranging from 4 kW to 30kW depending on the size of the system.

“Can the HyDAF dissolved air flotation system system handle large solids?”

It can but large solids can cause blockages and increase the chances of sedimentation occurring. In municipal applications we normally recommend the installation of a 1 -2 mm screen be installed upstream of the HyDAF dissolved air flotation system. For information on our range of screens, please click here.

“Is the HyDAF dissolved air flotation system easy to maintain?”

Yes the system can often be maintained by in-house personnel. Mechanically the HyDAF dissolved air flotation system rarely fails, the most common cause of poor performance is due to chemical programs malfunctioning which is usually due to changes in raw wastewater characteristics. Hydroflux can offer a service and preventative maintenance program if required via Hydroflux Utilities. Please click here for more info.

The modular screen design allows for easy retrofitting of additional filter surface areas to meet the ever increasing throughput requirements. For example within municipal applications with preliminary screening and preceding biological treatment a throughput capacity of up to 1500 m³/h can be achieved with 20 filter discs.

The screen is especially suited for applications where a very high filtrate quality and large filter surface area is required. Due to its small space requirement and modular design the RoDisc® Rotary Mesh Screen can be tailored to suit any specific site requirement

High hydraulic loads, insufficient tank depth and poor settling behaviour of the activated sludge are the most common causes for the poor performance of secondary clarifiers. Frequently, secondary clarifiers are even unable to reliably ensure the solids retention required. Under storm conditions for example, the amount of filterable solids can be up to three to four times the volume experienced under dry weather conditions. Overflow of flocks increases COD, BOD and phosphorus loads in the effluent and receiving watercourse with the result of higher wastewater fees.

Especially the increased concentrations of nutrients in surface waters, such as phosphate and nitrate, lead to eutrophication of water bodies and excessive growth of algae and water plants.

A subsequently installed micro screen is a quick, efficient and economical solution in order to achieve further separation up to a virtually solids-free effluent. Combined with preceding precipitation and flocculation a micro screen provides a quick and easy-to-implement means for the reduction of phosphorus in effluents to very low concentrations. This prevents eutrophication of waters and excessive growth of algae and water plants.

The RoDisc® Rotary Mesh Screen works on the basis of the well-proven drum filter principle. The wastewater to be treated flows through the filter discs from inside to outside. The filter discs remain in rest position at first during the filtration process. The solids are retained on the inner disc surfaces, which leads to gradual blinding of the mesh, resulting in an increasing pressure differential.

An overflow weir ensures that the water level in the tank remains virtually constant. The upstream water level rises as the blinding process progresses. When the predefined maximum pressure differential has been reached, the solids are removed automatically from the filter surfaces.

The solids are removed by the slow rotation of the filter discs combined with spray nozzle bars which wash the filtrate through the mesh from inside to outside without the need to use fresh water. The spray water and the solids contained are collected in a trough and discharged axially from the machine. The filtration process runs on continuously whilst the filter discs are being cleaned

-

- Screening with a defined separation size provided by a square mesh

- Gravity system

- Low headloss,

- High hydraulic throughput capacity

- No external wash water supply required

- Effluent standards are reliably met.

a

- Reduced wastewater discharge charges

- Reduction of filterable solids, COD, BOD, phosphorus

- For installation within a stainless steel tank or in customer’s concrete tank

- Compact, enclosed design

- Continuous operation principal

Micro screening of biologically treated wastewater

The RoDisc® Rotary Mesh Screen is frequently utilised for the separation of fine suspended material from biologically treated wastewater within municipal and industrial applications, especially if secondary clarifiers work insufficiently because they are too small or the settling behaviour of the activated sludge is poor for example. Our micro screens reliably achieve effluent values which are significantly bette rthan the required limit values for filterable solids.

Micro-screening to protect or increase the efficiency of downstream treatment systems.

A virtually solids-free flow is a prerequisite for effective and efficient as well as trouble and maintenance free operation of some subsequent treatment steps, such as UV disinfection or membrane filtration. Our micro screens significantly reduce the concentration of suspended material. Investment and operation costs are more than compensated because micro screening saves money for downstream systems.