Restoring Confidence in Tailings Management

July 9, 2024

Management of tailings has become a significant headache for mines across Australia and New Zealand over the course of this decade. There are approximately 250 active tailings facilities in Australia with significantly more inactive and historically, tailings facilities employed simple large-scale, low-cost sedimentation basins to manage tailings which are at the mercy of the elements and constant risk to the environment.

There are currently over 350 operating mines in Australia, and with critical mineral supply expected to double or quadruple to meet demand from clean energy systems by 2030 alone – this issue will worsen with this growth.

One of the most challenging aspects of tailings treatment is the removal of sparingly soluble sulphate (SO4), which is generated from the oxidation of waste rock and minerals. Typically, tailings, as well as acid mine drainage remediation have limits on sulphate and TDS discharges to the environment.

Traditional technology for removal of sulphate typically involves lime addition, which requires long contact times for precipitation of gypsum. In most instances, lime addition alone cannot reach the target sulphate limits required for environmental discharge. Alternatives, such as barium precipitation are also applied, but at significant operational cost for both the barium reagents and the management of the produced barium sulphate precipitate.

More recently, reverse osmosis and/or ion exchange treatment has been employed for sulphate management. These processes are relatively energy intensive, particularly when handling the significant volumes of waste brine generated by the process.

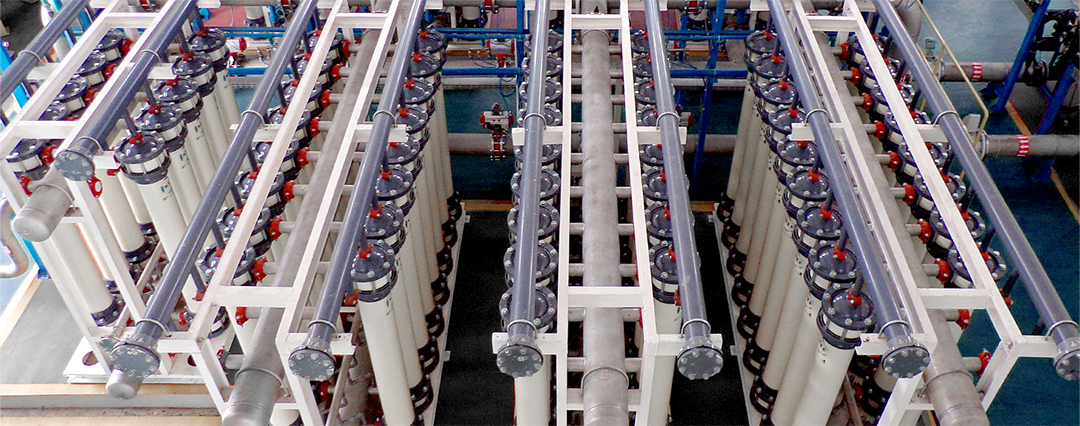

Hydroflux have a proprietary solution utilising NX Filtration’s novel direct hollow fibre nanofiltration membrane that overcomes these issues. Compared with current options the benefits of the Hydroflux – NX hollow fibre nanofiltration process include:

- Simultaneously remove metal, sulphates and TDS without impacting monovalent compounds such as sodium, potassium and chloride.

- Lower total ownership cost, more efficient process compared with equivalent performance from current industry alternatives such as lime and barium precipitation.

- Potential to recycle/recover valuable metals within the tailings waste whilst simultaneous treating water for compliant environmental discharge.

- Lower Energy consumption, more compact deployable solution compared with other membrane processes.

- Does not produce a waste salt brine stream

Hydroflux offer full piloting study capabilities for the NX system, as well as other inhouse technologies to determine the most appropriate solution for your tailings management. To find out more about Hydroflux mining solutions Click Here, or contact us on 1300 417 697 or email [email protected].

About the Hydroflux Group

The Hydroflux Group aims to deliver the highest level of engineering and scientific know-how to the emerging issues of sustainability, climate adaptation and environmental protection with a specific focus on water and wastewater.

As part of its vision and mission, Hydroflux has always taken its climate responsibility seriously. In 2022, Hydroflux became Australia’s first water treatment and technology company to achieve Climate Active carbon neutral certification for its organisation and products. It knows that partnering with customers and clients is the most significant impact it can have in its journey. The Group employs over 100 staff and operates throughout Australia, New Zealand and the Pacific Islands, with office locations in Sydney, Melbourne, Brisbane, Perth, Auckland, Suva and Portsmouth.

Up Next

Categories

- Tradeshows

- Climate

- Community Engagement

- Corporate Announcements

- Group News

- Newsletters

- Product News

- Project Announcement