HyPURE® Membrane Technology

Water and Wastewater Treatment Solutions Using Membranes and Filtration

Membrane filtration technologies play a crucial role in municipal water and wastewater treatment, providing high-quality effluent for discharge, reuse, and potable applications. Hydroflux Epco offers a full range of membrane solutions, including Microfiltration (MF), Ultrafiltration (UF), Nanofiltration (NF), and Reverse Osmosis (RO), ensuring municipalities achieve superior water quality and regulatory compliance.

Applications of Membrane Technology in Municipal Treatment

Hydroflux Epco’s membrane filtration solutions support a range of municipal applications.

Drinking Water Treatment – Ensuring safe and high-quality potable water supply.

Wastewater Reuse and Recycling – Enabling municipalities to reclaim treated wastewater for irrigation and indirect potable reuse.

Desalination – Providing sustainable freshwater sources from seawater and brackish water.

Stormwater and Surface Water Treatment – Improving water quality for municipal and environmental discharge.

Hydroflux Epco’s Expertise in Membrane Technology

Hydroflux Epco collaborates with world-leading membrane manufacturers, ensuring high-performance filtration solutions tailored to municipal water and wastewater treatment needs. Our membrane solutions offer:

- Customised system designs for new installations and upgrades to existing treatment facilities

- Integration with advanced pre-treatment processes to optimise membrane performance and lifespan

- Automated control systems for efficient operation, monitoring, and maintenance

- Local support and readily available spare parts to ensure long-term reliability and performance

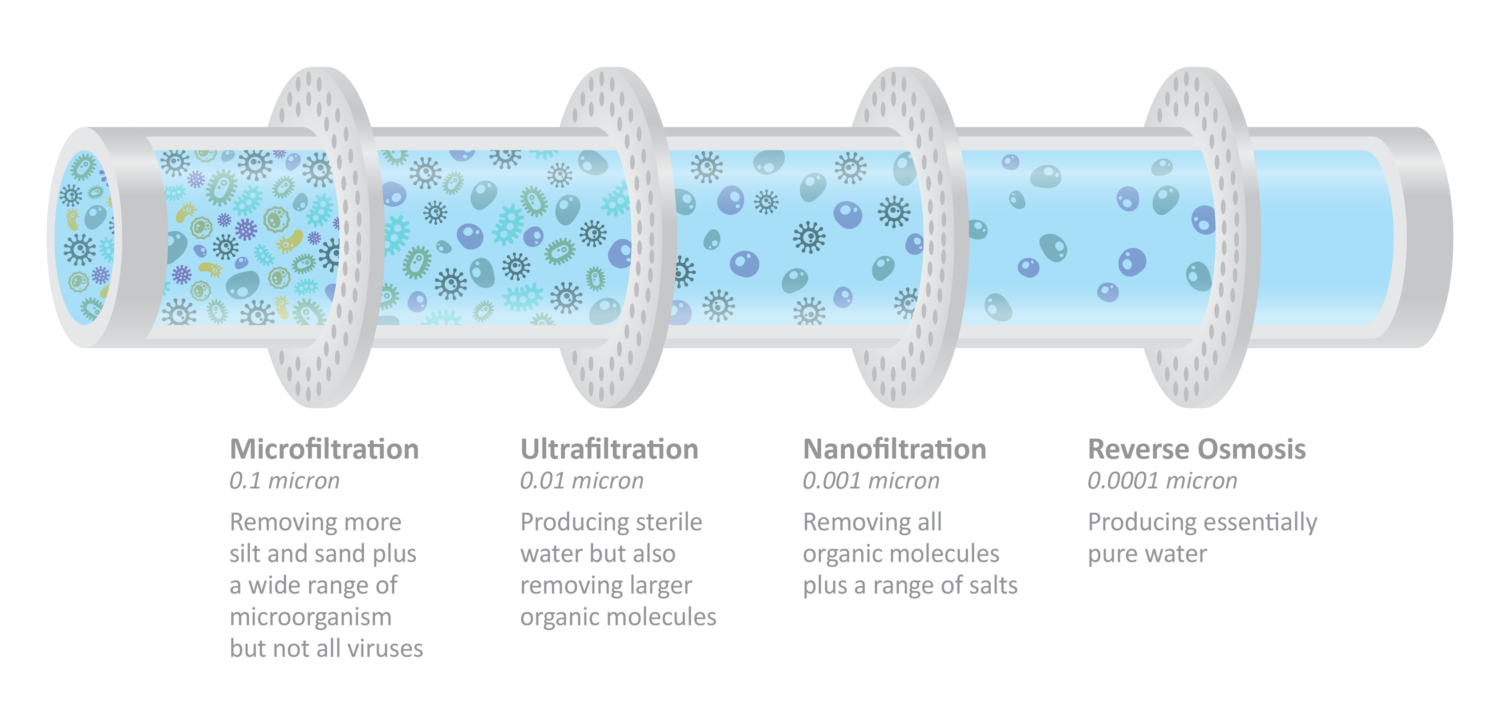

The Spectrum of Membrane Filtration

Membrane filtration is a key technology in water and wastewater treatment, offering a spectrum of filtration levels from Microfiltration (MF) to Reverse Osmosis (RO). Microfiltration (MF), with pore sizes between 0.1–10 µm, removes larger particles such as bacteria and suspended solids while allowing dissolved salts and smaller molecules to pass through. Ultrafiltration (UF), with smaller pores (0.01–0.1 µm), effectively removes bacteria, viruses, and fine particulates, making it ideal for drinking water treatment, wastewater recycling, and industrial water purification.

Nanofiltration (NF) and Reverse Osmosis (RO) provide higher levels of filtration for more advanced applications.

NF, with a pore size of 0.001–0.01 µm, removes larger dissolved ions, organic matter, and micropollutants while allowing smaller monovalent salts (e.g., sodium, chloride) to pass, making it suitable for water softening and micropollutant removal.

RO, the most advanced membrane process, has pores smaller than 0.001 µm and removes nearly all dissolved salts, heavy metals, and organic contaminants, producing high-purity water for desalination, ultrapure water production, and wastewater reuse.

Hydroflux provides tailored membrane filtration solutions for municipal and industrial applications, ensuring efficient, cost-effective, and sustainable water treatment. With the right combination of MF, UF, NF, and RO, water treatment plants can achieve superior water quality, reduce environmental impact, and optimise operational efficiency.

| Membrane Type | Pore Size | Removes | Allows Through | Applications |

|---|---|---|---|---|

| Microfiltration (MF) | 0.1–10 µm | Bacteria, suspended solids | Viruses, dissolved salts | Pre-treatment, wastewater clarification, food processing |

| Ultrafiltration (UF) | 0.01–0.1 µm | Bacteria, viruses, colloids | Dissolved salts, small organic molecules | Drinking water, wastewater recycling, industrial processing |

| Nanofiltration (NF) | 0.001–0.01 µm | Viruses, hardness, large ions, organics | Small monovalent salts (Na+, Cl−) | Softening, micropollutant removal, moderate desalination |

| Reverse Osmosis (RO) | <0.001 µm | Nearly all dissolved salts, organics, heavy metals | Very few molecules (H₂O only) | Seawater desalination, ultrapure water production, wastewater reuse |

HyPURE NX – Direct Nanofiltration (NF) with NX

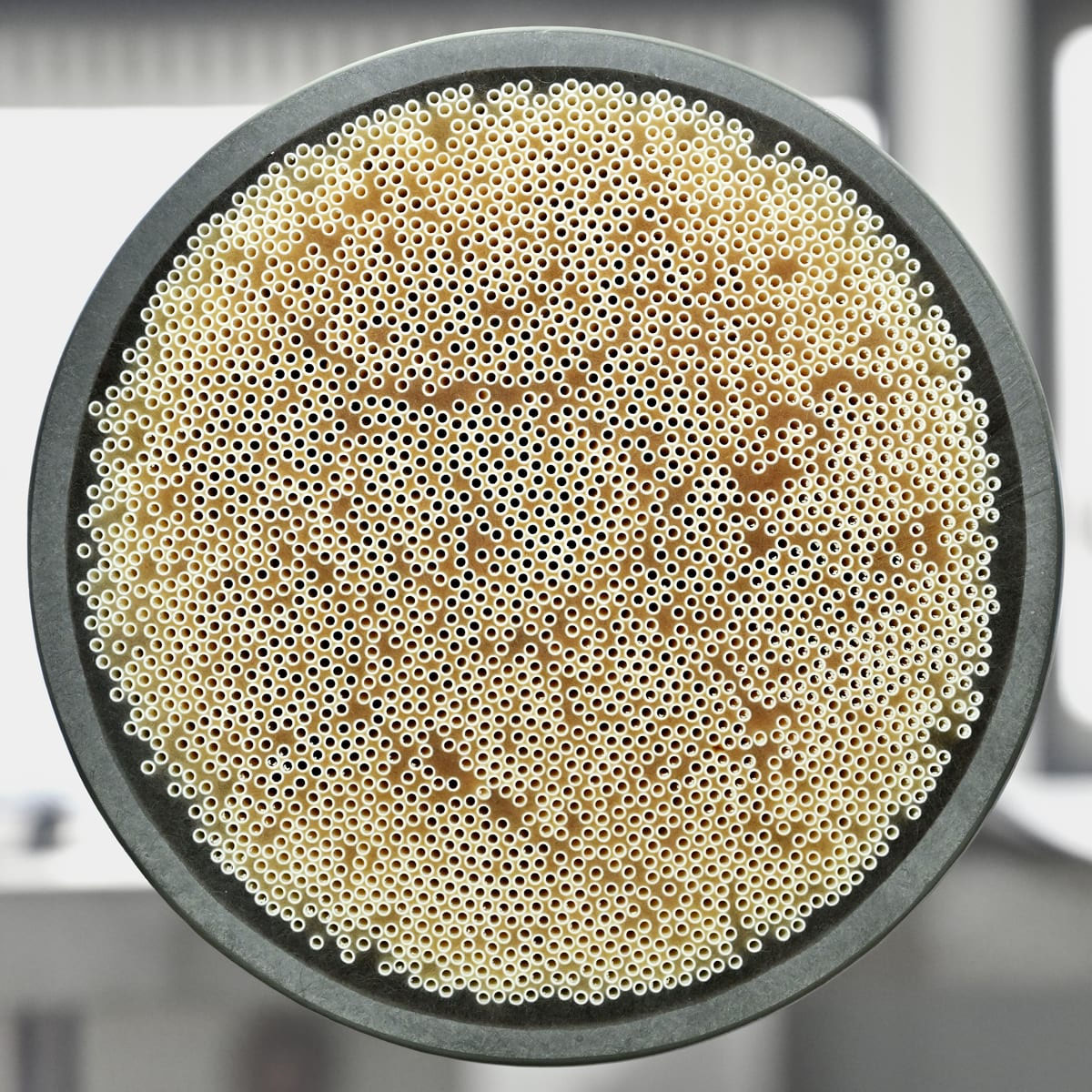

Hydroflux Epco proudly offers HyPURE NX direct nanofiltration membranes, developed through our partnership with NX Filtration. These hollow fibre membranes represent a breakthrough in cross-flow filtration, offering an alternative to traditional spiral-wound NF systems.

The HyPURE NX uses direct nanofiltration hollow fiber membranes that can remove organics, hardness, micro-pollutants, colour, medical residues, PFAS and endocrine disruptors from contaminated water streams. Unlike RO systems, HyPURE NX does not target the rejection of dissolved inorganic salts and will often achieve a suitable water quality for discharge or high-quality reuse without the challenges associated with the production and costly disposal of a concentrated salt or brine stream.

Key Advantages:

- Removes organics, colour, PFAS, pharmaceuticals, endocrine disruptors, and partial hardness

- Retains beneficial salts for lower brine production compared to RO

- Backwashable hollow fibre design increases fouling resistance

- Chemically robust, allowing cleaning with strong oxidants like chlorine

- Green manufacturing with water-based coating chemistry

Applications:

- Process and industrial water reuse

- PFAS and micropollutant removal

- Metal and sulphate removal

- Pre-treatment for demineralisation systems

What Sets NX Membranes Apart?

The innovative construction of NX membranes offers significant advantages over alternative designs. The membrane base material, poly-ether-sulphone (PES), is known for its exceptional mechanical strength and produces membranes with extremely small pore sizes and a narrow pore size distribution. The PES base is further enhanced by a selective nanolayer coating, created using water-based electrolytes.

Unlike spiral-wound elements, the hollow-fiber configuration of NX membranes eliminates obstructions caused by spacers, enhancing fouling resistance. A unique feature of these hollow-fiber membranes, particularly for nanofiltration processes, is their ability to be backwashed.

HyPURE NX membranes also feature advanced chemistry that allows for continuous operation and cleaning with strong oxidants, such as chlorine and hydrogen peroxide, across a wide pH range—from very high to very low. This makes them both versatile and durable in challenging operating environments.

Types of HyPURE NX Membranes

There are two types of HyPURE NX membranes, the dNF80 and dNF40. The dNF80 (800 Dalton MWCO) is typically used for NOM (color) removal, whilst the denser dNF40 (400 MWCO) is suitable for micropollutant removal and partial demineralization of water. Both types are available in modules of DN 110 and DN 200 with a membrane area of up to 50 m² and a membrane fiber internal diameter of 0.7 mm. Modules are operated in cross-flow mode with a cross-flow velocity of ≤0.5 m/s and a maximum transmembrane pressure (TMP) of 6 bar.

Contact Hydroflux Epco to Discuss Membrane Treatment

With extensive experience in designing and delivering membrane-based water and wastewater treatment systems, Hydroflux Epco offers the technical expertise, local support, and innovative technologies needed to ensure reliable, efficient, and sustainable outcomes. Our partnerships with leading global manufacturers give clients access to the latest in membrane filtration, including advanced solutions like HyPURE NX.

Whether you’re planning a new installation or upgrading an existing facility, we provide tailored support from concept to commissioning and beyond.

Contact Hydroflux Epco today to learn how our membrane technologies can enhance the performance, compliance, and sustainability of your water treatment operations.